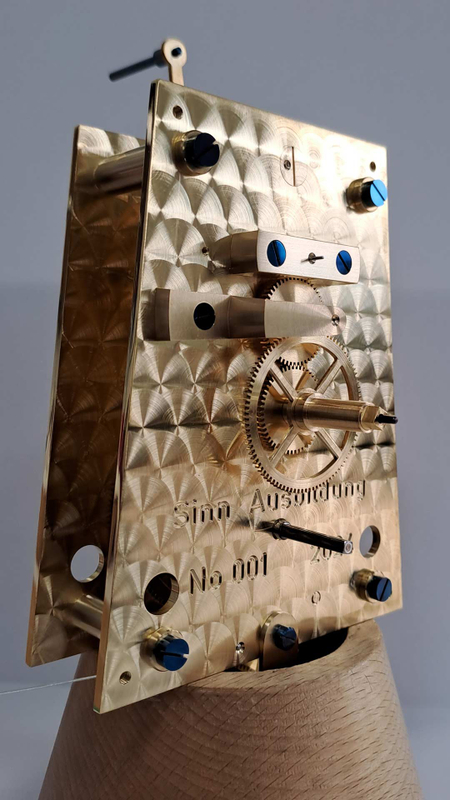

- Height 80 cm, width 25 cm, depth 14 cm

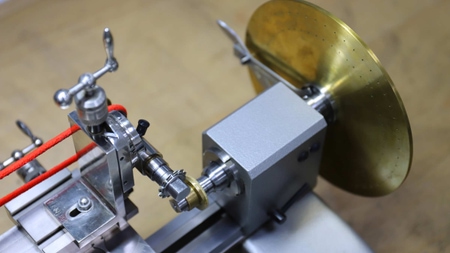

- Cable pulley regulator with loose castor, ball bearing

- Counter locking gear for continuous force transmission during winding

- Graham escapement

- Carbon pendulum rod with ultra-low coefficients of expansion and adjustment nut for fine adjustment

- Perlée finish on plates (outside and inside)

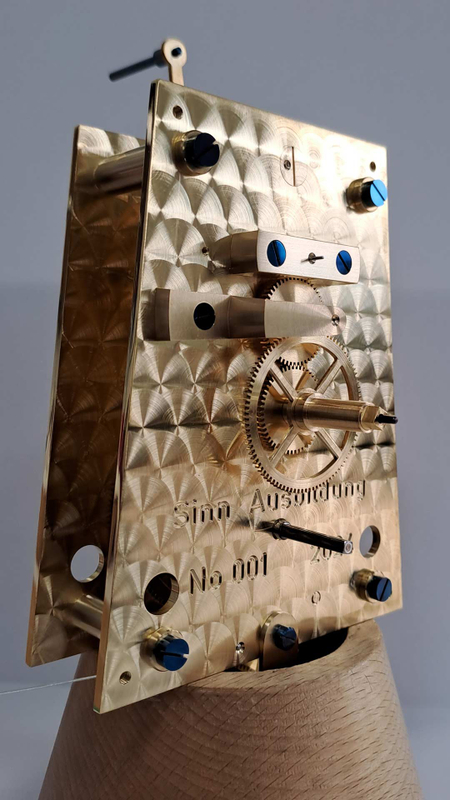

- Polished and blued screws

- Polished and cambered hands

- Solid wood case in nut, oak or cherry with side glazing

- Nickel silver dial with hand-made, gold-plated appliques

Watchmaking master training

SINN trainees build their own pendulum wall clocks.

Quality as the key to success – this is the philosophy that lies at the very heart of watchmaking training at Sinn Spezialuhren. The aim is to unite cutting-edge technology with the traditional art of watchmaking. At the same time, the company is renowned for its impressive training standards, which already demonstrate a high level of mastery. The pendulum wall clock project, which is currently one of a kind among training companies in Germany, is the perfect example of this. Under the expert guidance of Sinn Spezialuhren training manager Jessica Schmitt and trainer Hermann-Josef Müller – and for the first time in the company’s training history – trainees worked to a professional level at every single step, from movement to case, from hands to pendulum rod. Problem-solving skills, creativity and a great deal of ingenuity were the order of the day.

Targeted vocational training boosts motivation

How can training content that goes beyond the conventional standards take shape in practice? What object from the watchmaking trade could best be used to achieve this? Such questions had played on Hermann-Josef Müller’s mind for a long time. After discussing the matter with owner Lothar Schmidt, it became clear that a pendulum wall clock was the perfect answer. It may be useful to point out here that watchmaking training starts with pure metalworking. Filing, milling, grinding and turning are the first skills that are fundamental to the trade. Pendulum wall clocks are perfect for honing these; working on and with watches follows later in the training programme. Hermann-Josef Müller also saw another advantage: ‘Trainees tend to practise these skills on work pieces or models that have no practical use once they have been worked on. If, on the other hand, the parts were to be used for a pendulum wall clock that trainees had to build themselves, these new abilities would suddenly take on a new significance. Motivation goes up a gear, too. Both of these aspects carry the trainees through the entire training programme.The blued screws were made in a special in-house bluing process.

A project with unexpected challenges

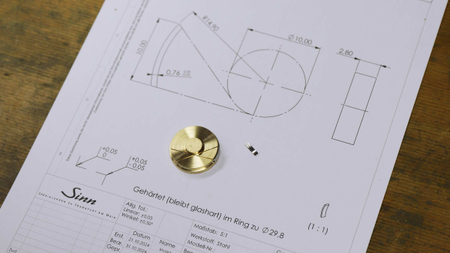

Cable pulley, Graham escapement and counter locking gear: These were just some of the special features that Hermann-Josef Müller envisioned for the clock (see info box on the penultimate page). However, no sooner had the decision been made than the first obstacles presented themselves during the preparation and planning phase in summer 2021. Indeed, such events were to become common occurrences throughout the entire project, forcing the participants to think outside the box and change direction several times. The search for a model upon which to base their own designs proved trickier than expected. Finally, an old regulator belonging to a colleague met the defined criteria. However, there were no technical drawings or plans that the trainees could use to help them with their own professional designs. So what could be done? Hermann-Josef Müller dismantled the clock into individual parts and took photographs of each of them. Armed with a caliper gauge and other measuring tools, he noted down all of the main measurements of the movement and – having gathered more than 100 – instructed staff in the development department to record them in technical drawings.Sourcing machines

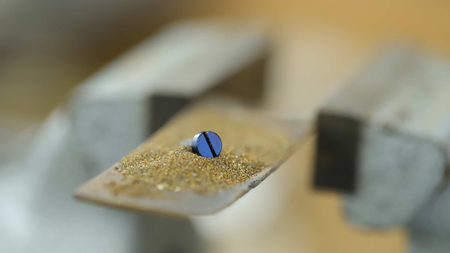

The implementation phase began with the 2022 training cohort. However, their enthusiasm was curbed by another stumbling block: the difficulty in finding suitable machines. ‘We needed a special and rarely used gearwheel cutting machine. However, with a lot of patience and luck, and after a painstaking search of Switzerland, we were finally able to source literally the last existing model. It was pretty old, but it worked. We also had to buy another watchmaker’s lathe and a precision bench drill. To help the project along, Lothar Schmidt approved these investments without delay.’ However, the gearwheel cutting machine had none of the accessories required to make the gears and drives in the first place. Once again, the team improvised and managed to draft some plans, which were subsequently used to make the missing parts in the SINN workshop.

Finding creative solutions

Parallel to solving the technical tasks, the trainees also had to think about the aesthetic design and construction of the case. Hermann-Josef Müller began by creating a draft that was subsequently turned into a CAD drawing. A joiner then used the drawing to make construction kits in oak, walnut and cherry. Next, master joiner Frank Leipold, trainers Jessica Schmitt and Hermann-Josef Müller and the trainees came together at a seminar that focussed on surface treatment, sanding and oiling. This also doubled as a crash course in woodworking. The team also had to learn for themselves how to assemble the case and make a special holding frame for fixing the front to the wooden panelling for the door.

As a result of the production framework conditions and design freedom, every grandfather clock created by the individual trainees is a true one-off, each with its own unique hands and dials, for instance. ‘This means we achieved 100% vertical integration in our own training centre. And it is important to emphasise that such a project, together with all of its highly complex steps, really is at the highest level of mastery. Making a pendulum wall clock like we do goes far beyond the normal scope of watchmaker training. Although master watchmaker training does involve building their own clock, the gearwheels are provided, whereas our trainees have to make them from scratch themselves. We did everything ourselves from the very beginning. The skills and problem-solving abilities learned throughout the process are optimal preparation for subsequent trade and master qualifications. As a result of this, our trainees now have a clear advantage over other companies that don’t give them this opportunity. And the fact that our trainees often achieve above-average results serves as further proof of the high quality of our training programme,’ confirms Hermann-Josef Müller with pride.

Preserving the art of watchmaking

All of this is possible because one of the corporate goals of Sinn Spezialuhren is to ‘promote the use and preservation of traditional crafts, especially the watchmaking craft’. The pendulum wall clock project is therefore the perfect expression of this. It also ties in with the fact that UNESCO has included the watchmaking craft in its Representative List of the Intangible Cultural Heritage of Humanity. In other words, the project also serves as an investment in the future of the craft itself. At the same time, it makes an active contribution to the continued existence of the company by training future specialists. Its high internal importance is also evident in the fact that trainees dedicate the first two years of their training to the project, even if it does not directly contribute to the company’s value creation. But it is definitely worth it!The dial of this pendulum wall clock is made of nickel silver. The indices are made of brass. They were filed before being gold-plated. The hands are made of steel, which was subsequently blued. The trainee designed and made the dial himself.

Continuous development in the future

This is a typical SINN story on another level, too: Fourteen years ago, Jessica Schmitt started her watchmaker’s training at Sinn Spezialuhren and successfully gained her master qualification. Hermann-Josef Müller recognised her talent for the profession early on, and encouraged her throughout her entire training. This gave way to the perfect generational change in training management at Sinn Spezialuhren. Jessica herself looks back on her time as a trainee wistfully. ‘Repairing and reconditioning old watches brings me a lot of joy. But having the chance to design and build one myself is something I would love to have done during my training.’ And even though the first SINN pendulum wall clock was finally finished by third-year trainees this year, the design is constantly being re-tweaked and improved. The escape wheel bridge for the second model has already been redesigned by a trainee, with a cut-out in the plate now making the escapement visible during the transmission of force to the pendulum.Change of generation: Jessica Schmitt has taken over from Hermann-Josef Müller as training manager

‘Being a watchmaker means having an insatiable thirst for rethinking things and finding new ways. Building a pendulum wall clock gives us the opportunity to learn a great deal that you can’t find in a book. Ultimately, everyone involved helps to lay the foundations for understanding mechanics as a whole’

Jessica Schmitt, trainer